Aaki and QEMR: Innovating Solutions for Vertical Hollow Shaft Motor Protection

Quality Electric Motor Rebuilders (QEMR), based in Barrie Ontario, Canada,...

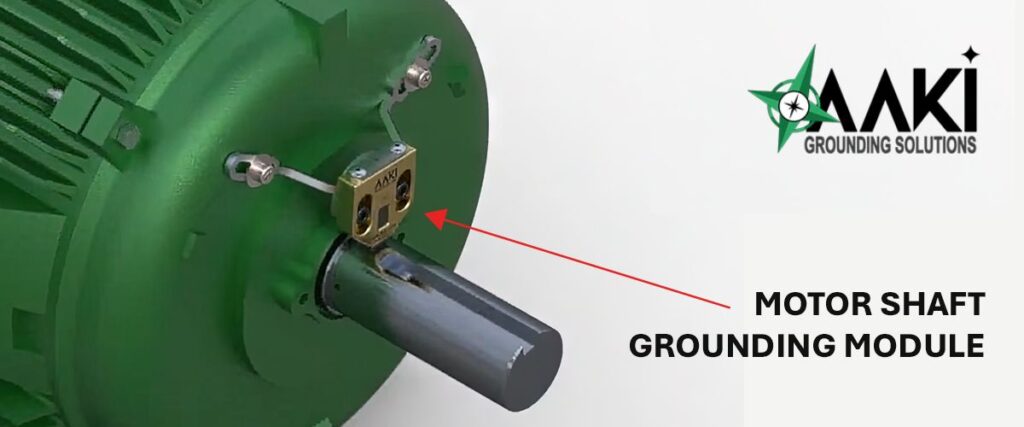

When it comes to protecting induction motors from electrical discharge machining (EDM) damage, motor shaft grounding modules (MSGMs) are indispensable. However, beyond the initial purchase price, the true value of an MSGM lies in its total cost of ownership (TCO), which includes installation, maintenance, and overall performance. Aaki’s MSGMs offer a significant advantage with their innovative mounting solutions that reduce installation time and, consequently, lower the total cost of ownership. This article will explore why Aaki’s MSGMs are the optimal choice for reducing costs and mitigating risks, especially in an industry facing challenges in skilled labor availability.

The cost of installing an MSGM is not just the price of the module itself but also the labor and time required to mount it correctly. Traditional MSGMs can be challenging to install, especially on motors with sloped or limited mounting surfaces. A poorly installed module can lead to ineffective grounding, increased maintenance needs, and ultimately, motor damage.

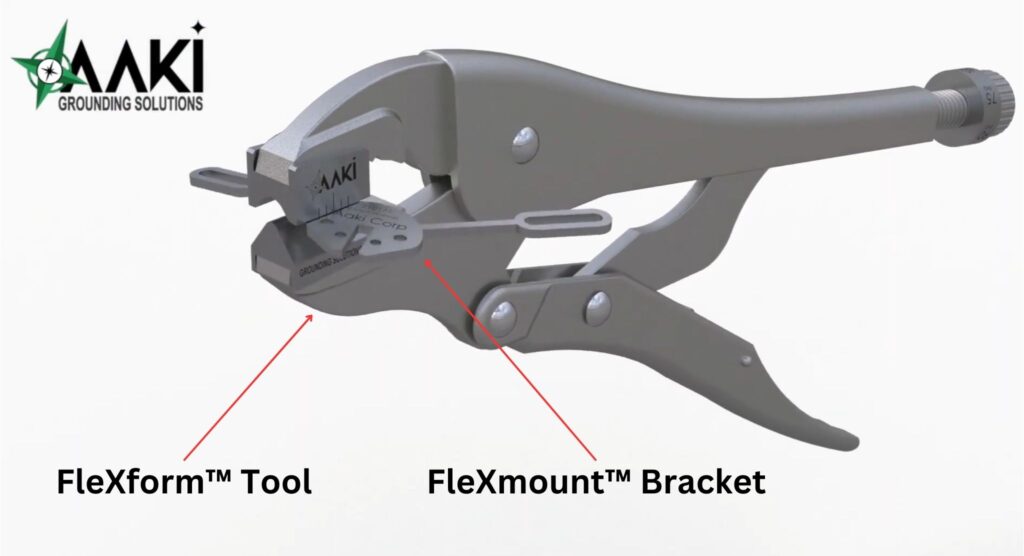

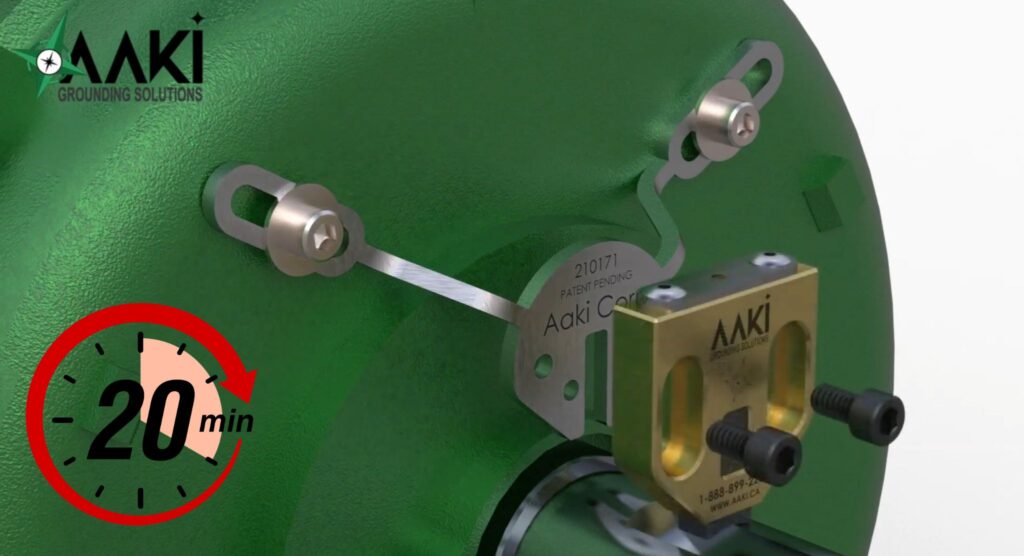

Aaki has developed an innovative mounting solution using FleXmount™ brackets and the FleXform™ tool, which simplifies the installation process. These brackets can be quickly and precisely shaped to fit the motor’s geometry, ensuring that the MSGM is positioned correctly and securely. This reduces installation time significantly, cutting down on labor costs and minimizing the risk of improper installation.

Motor repair shops are currently facing a significant challenge: a shortage of skilled technicians who can perform complex installations like those required for MSGMs. This shortage leads to several issues:

Simplified Installation Process

The ease of use provided by Aaki’s FleXmount™ brackets and FleXform™ tool means that even less experienced technicians can achieve a proper installation. The brackets can be bent to the exact shape needed, ensuring that the MSGM is mounted away from shaft defects such as keyways and that the grounding brush maintains consistent, perpendicular contact with the shaft. This reduces the potential for installation errors and ensures optimal performance, even with a less experienced workforce.

Reducing Installation Time: A Key Cost-Saving Factor

Time is money, especially when it comes to motor maintenance and repairs. The time saved during installation directly translates into reduced labor costs and less downtime for the motor.

Fast, Accurate Installation with Aaki’s FleXmount™ System

The FleXmount™ system allows for quick adjustments and precise alignment, which are crucial for reducing installation time. The FleXform™ tool further enhances this by enabling technicians to bend the bracket to the exact required shape on-site, minimizing the need for additional tools or adjustments. This not only speeds up the installation process but also reduces the overall cost associated with labor and downtime.

A poorly installed MSGM is more than just a financial risk—it can lead to severe operational consequences. Improper installation can cause the grounding brush to lose contact with the motor shaft, leading to ineffective grounding and potential motor damage. This can result in:

Aaki’s MSGMs, combined with FleXmount™ brackets and the FleXform™ tool, provide a complete solution that reduces the total cost of ownership through faster, easier, and more reliable installation. This not only saves on labor costs but also mitigates the risks associated with poor installation, ensuring that motors are protected and operate reliably for longer periods.

For motor repair shops and facilities struggling with skilled labor shortages, Aaki’s MSGMs offer a way to lower costs, reduce downtime, and maintain high standards of motor protection with less reliance on specialized skills. Investing in Aaki’s MSGMs is an investment in efficiency, reliability, and long-term cost savings. Contact Aaki today to learn more about how our innovative solutions can benefit your operations.

Quality Electric Motor Rebuilders (QEMR), based in Barrie Ontario, Canada,...

HVAC (Heating, Ventilation, and Air Conditioning) refers to systems that...

We’re thrilled to announce that AAKI will be there. We...

Be First To Find Out About Our News And Promotions.

Copywrite © 2025 Aaki Corp. All rights reserved.

1 thought on “Understanding the Total Cost of Ownership of Motor Shaft Grounding Modules (MSGMs) ”

Good article.