Aaki and QEMR: Innovating Solutions for Vertical Hollow Shaft Motor Protection

Quality Electric Motor Rebuilders (QEMR), based in Barrie Ontario, Canada,...

Industrial motors are indispensable across all industries, powering production lines and keeping machinery running. However, the built-in-design of these motors, particularly those regulated by Variable Frequency Drives (VFDs), poses a serious risk: electrical discharge through the bearings. VFDs adjust the frequency of the electrical supply to control motor speed, but this variability can generate unwanted electrical currents along the motor shaft.

Need for Motor Shaft Grounding

Shaft voltage is a common challenge in electric motors and generators, often stemming from leakage, induction, or capacitive coupling with motor windings. This phenomenon is particularly prevalent in motors used in HVAC, industrial conveying, and other systems where the motor speed and torque is controlled by a VFD. Without proper intervention, this buildup can trigger harmful electrical discharges that manifest as small sparks arcing through the bearings. Over time, these discharges cause microscopic pitting on the metal surfaces of the motor’s bearings, gradually increasing friction and ultimately leading to their failure.

Aaki Corp’s Motor Shaft Grounding Module (MSGM) provides a solution to this problem. Drawing on over thirty years of grounding technology experience, Aaki Corp’s MSGM helps protect the degradation of motor components from the damaging effects of shaft voltage.

Key Features of AAKI CORP’s Motor Shaft Grounding Module

Superior Construction

Aaki Corp’s motor shaft grounding modules are designed with durability in mind. Machined from a solid block of aluminum bronze, the modules are well built and corrosion-resistant to stand up to demanding industrial environments.

The module’s high copper content, graphite brush, provide excellent conductivity, offering very low resistance and supporting high current flow. This material combination provides excellent performance in its ability to protect motor bearings from damaging electrical currents. The brush is contoured to fit on the motor shaft, reducing installation time.

Innovative Brush Life Window™ Technology

Central to the MSGM’s design is the Brush Life Window™ – designed with the maintenance operator in mind. This feature allows operators to visually assess the wear on the grounding brush in real-time. Traditional methods often involve disassembly of the device to perform periodic inspections or estimations taking up significant time, but Aaki’s Brush Life Window™ allows evaluations in seconds and removes the guesswork, saving the operator his most valuable resource – time.

Ease of Installation and Compatibility

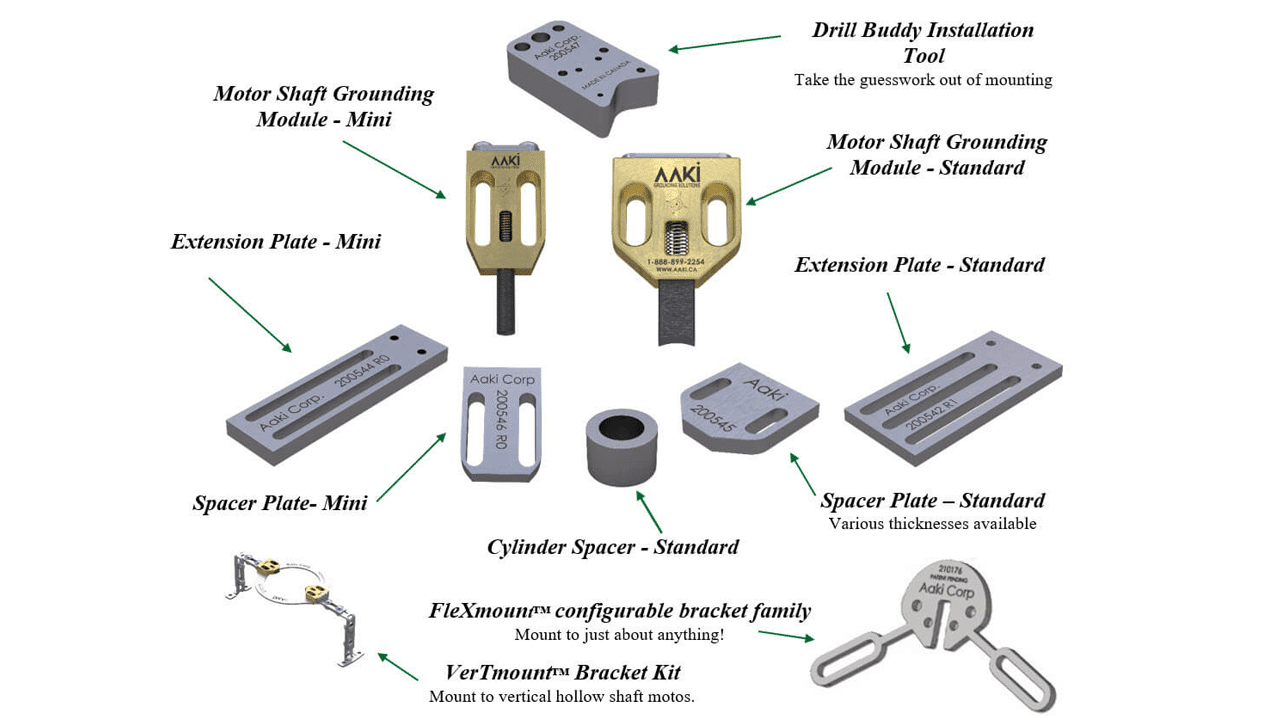

Mounting any device on a motor can be a challenge. Motors come in a wide range of shapes and sizes, making mounting a MSGM a time consuming, difficult operation that typically needs to be performed by a trained technician. Aaki’s family of mounting brackets, spacers and extension plates, takes the guesswork and time out of the mounting process. A significant step forward in making mounting quick and easy is the FleXmount™ bracket system. With the FleXform™ tool, this bracket can be bent to almost any shape, easily conforming to the motor endbell shape and allowing for a perfect fit every time. A quick and repeatable solution that saves the customer time and effort.

Technical Specifications and Performance

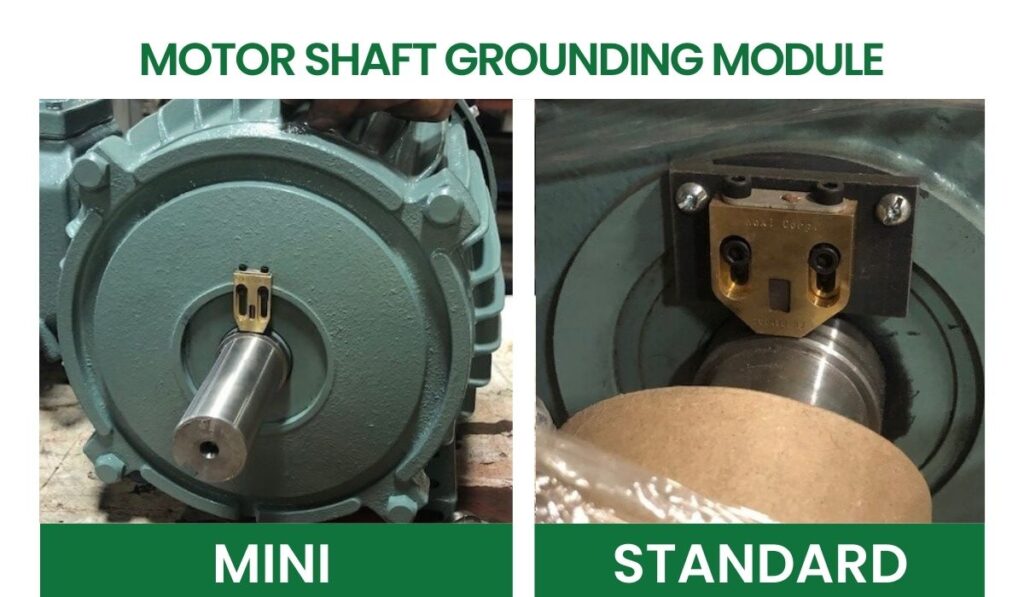

There are two basic sizes of Motor Shaft Grounding Modules. The “Standard” measures 1.4” X 1.7” X .4” and features a large brush surface area. This module is designed to carry up to 10 amps of generated shaft currents. The “Standard” is the go-to module for most applications and can be used on motors ranging from fractional horsepower to hundreds of horsepower. The “Mini”, at less than a ¼” thick, is designed to fit into tight spaces and provides bearing protection on fractional and small horsepower motors.

Custom Solutions for Industry-Specific Requirements

Aaki recognizes the diverse needs of its clientele across various industries. Motor Shaft Grounding Modules can be designed to specific motor models and configurations. Aaki’s team collaborates closely with clients to develop solutions that address specific operational needs. This custom approach ensures that each MSGM is fit for purpose and enhances the operational longevity and efficiency of the motors it protects.

Contact Aaki Corp for solutions to your motor shaft grounding challenges.

Quality Electric Motor Rebuilders (QEMR), based in Barrie Ontario, Canada,...

HVAC (Heating, Ventilation, and Air Conditioning) refers to systems that...

We’re thrilled to announce that AAKI will be there. We...

Be First To Find Out About Our News And Promotions.

Copywrite © 2025 Aaki Corp. All rights reserved.