Static Bonding and Grounding Reels: Essential Safety Tools

Static electricity may seem harmless, but in industrial environments it...

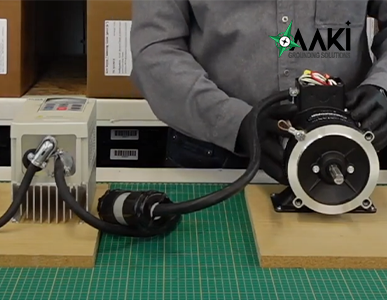

Variable Frequency Drives (VFDs) have become an invaluable tool in the modern industrial landscape, particularly for induction motors. By allowing precise control over motor speed and torque, VFDs help increase energy efficiency and optimize performance. Industries that depend on heavy-duty equipment, from manufacturing plants to oil and gas facilities, benefit from VFDs as they provide better control over motor operation and enable process improvements, all while reducing energy consumption.

However, this technological advancement comes with some hidden challenges. While VFDs have revolutionized the use of induction motors, they introduce a significant problem: the generation of unwanted shaft voltages. Facility managers and plant operators must understand how these voltages affect motor performance and longevity—and, more importantly, how to mitigate these effects.

When VFDs drive induction motors, they often generate high-frequency voltage pulses that can cause electrical discharge on the motor shaft. These voltages are particularly problematic because they create paths of least resistance through critical motor components like bearings. As this voltage accumulates, it can discharge across the bearing surfaces, causing electrical discharge machining (EDM). This effect manifests as fluted bearing races and frosted bearing surfaces, leading to accelerated wear, premature motor failure, and costly downtime for industrial operations.

In plants where uptime is critical, such as in oil refineries or chemical processing facilities, any unscheduled maintenance due to bearing failure can be highly disruptive. While VFDs offer many advantages, the risk they pose to motor bearings must be addressed proactively.

When a VFD-induced voltage passes through standard steel bearings, it leads to the rapid degradation of these components. The bearing races become pitted and damaged, reducing their lifespan dramatically. Even with well-maintained lubrication and cooling, standard bearings are highly susceptible to electrical erosion, which can ultimately result in bearing failure.

Replacing damaged bearings is not only costly but also requires significant downtime, which could impact production schedules. This is where alternatives such as ceramic bearings are often considered by facility managers looking to mitigate the issue of shaft voltage.

Ceramic bearings have been touted as a solution to VFD-induced shaft voltages. These bearings provide electrical insulation due to their non-conductive nature, isolating the motor shaft from the rest of the motor. In theory, this prevents the discharge of shaft voltage through the bearing and offers longer bearing life under certain conditions.

However, ceramic bearings are not without significant drawbacks. For one, they are considerably more expensive than standard steel bearings, sometimes costing up to five times as much. Additionally, they are not a standard item and come with long lead times, complicating procurement and potentially delaying repairs. Once installed, ceramic bearings often require specialized maintenance that may necessitate new processes and procedures in plant operations. Plant operators must ensure that maintenance personnel are trained to handle ceramic bearings, adding complexity to the overall maintenance plan.

Most importantly, while ceramic bearings may reduce shaft voltage within the motor, they don’t address the root cause of the problem—they merely isolate one component.

The most pressing issue with ceramic bearings is that they do not prevent shaft voltage from traveling elsewhere. The voltage will still seek a path to ground, often moving downstream through connected equipment. Whether it’s pumps, fans, pulleys, or conveyor belts, the risk of damage persists. Additionally, ceramic bearings do nothing to mitigate the high-frequency noise generated by VFDs, which can interfere with sensitive electronics, communication systems, sensors, PLCs, and even wireless devices.

When ceramic bearings isolate the motor shaft, the problem doesn’t disappear—it moves. Shaft voltages that aren’t discharged through the motor bearings can travel into any electrically connected equipment. This includes mechanical systems like pumps, compressors, and gearboxes, as well as electronic equipment such as control systems, communication networks, and sensors. The end result is that the same voltage that could damage motor bearings now poses a threat to a much wider range of industrial equipment.

Additionally, shaft voltage can cause high-frequency electrical noise. This noise can interfere with nearby electronic systems, leading to communication errors, inaccurate sensor readings, and malfunctions in process control equipment like PLCs. The potential for operational disruptions caused by this noise is significant, particularly in high-tech facilities where reliable communication and data accuracy are critical to productivity.

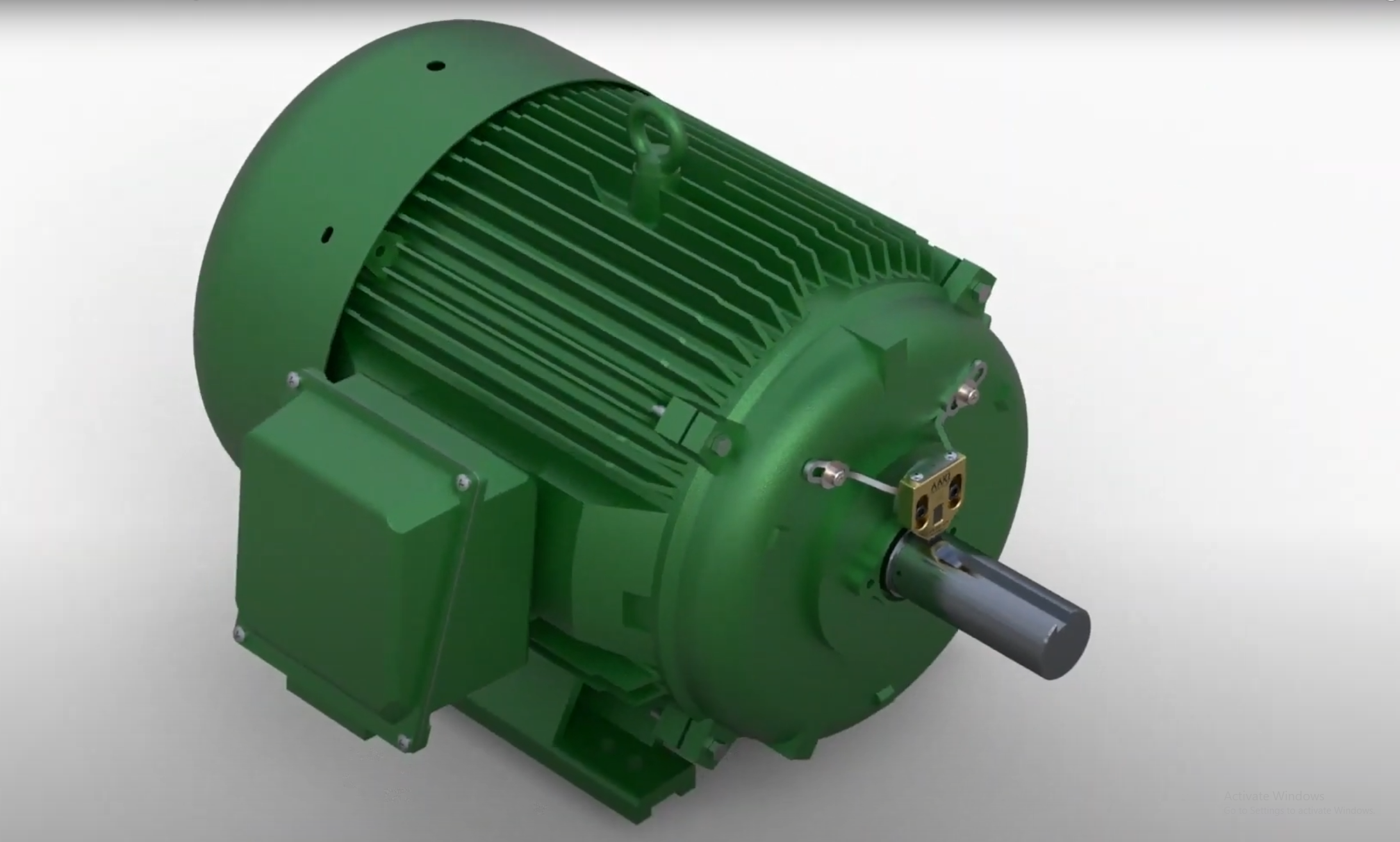

Rather than trying to isolate the shaft voltage, the best solution is to provide a safe path for it to dissipate. The Aaki Motor Shaft Grounding Module (MSGM) achieves this by bonding the shaft to ground and bypassing the bearings entirely. This method ensures that shaft voltage is discharged safely and prevents damage to both the motor bearings and any downstream equipment.

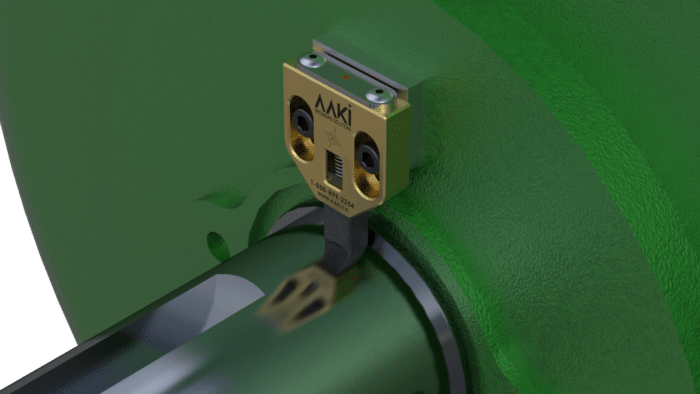

The Aaki MSGM is designed to be easy to install and maintain, making it a practical choice for plant operators and facility managers. The module consists of a conductive brush that rides perpendicular to the motor shaft, allowing for consistent grounding. The MSGM is mounted in such a way that it avoids common installation challenges, such as minimal space around motor endbells or interference from keyways.

One of the key benefits of the Aaki MSGM is its cost-effectiveness. While ceramic bearings are expensive and offer only a partial solution, the MSGM provides a reliable and affordable alternative. Installation is straightforward, with parts that are readily available and easy to source. Moreover, ongoing maintenance is minimal, allowing plant operators to focus on other critical aspects of facility operations without worrying about frequent downtime for motor repairs.

For facility managers and plant operators, protecting induction motors and connected equipment from VFD-induced shaft voltage is a critical concern. While ceramic bearings may offer some insulation, they come with high costs, specialized maintenance requirements, and do not prevent downstream damage or high-frequency noise. The Aaki Motor Shaft Grounding Module offers a comprehensive, cost-effective solution by safely grounding shaft voltage and bypassing motor bearings altogether.

With its ease of installation, minimal maintenance requirements, and superior performance, the Aaki MSGM is the ideal choice for ensuring the longevity of your motors and protecting your facility’s equipment from the detrimental effects of VFD-induced shaft voltage.

Static electricity may seem harmless, but in industrial environments it...

Quality Electric Motor Rebuilders (QEMR), based in Barrie Ontario, Canada,...

HVAC (Heating, Ventilation, and Air Conditioning) refers to systems that...

Be First To Find Out About Our News And Promotions.

Copywrite © 2025 Aaki Corp. All rights reserved.