With the introduction of variable frequency drives (VFDs) for electric motors, bearing damage from shaft voltages has become a significant concern to facility managers, plant operator and motor repair shops. The cost associated with motor repairs due to frosted or fluted bearings goes way beyond the cost of bearings or even down time.

Motor repair shops loose valuable trust with their customers when motors that have been properly serviced and repaired fail in as little as 3 months.

In the search for answers, VFD suppliers point to the motor design, motor manufacturers blame the VFD supplier, and everyone is looking at the motor repair shop for answers.

Facility managers, HVAC technicians, plant operators (and really anyone that manages or maintains a three phase motor) are under tremendous pressure to solve these problems. There isn’t an easy way to find the root cause, but the problem keeps recurring, operations are down, and time and money keeps slipping through the cracks.

There has to be a better way...

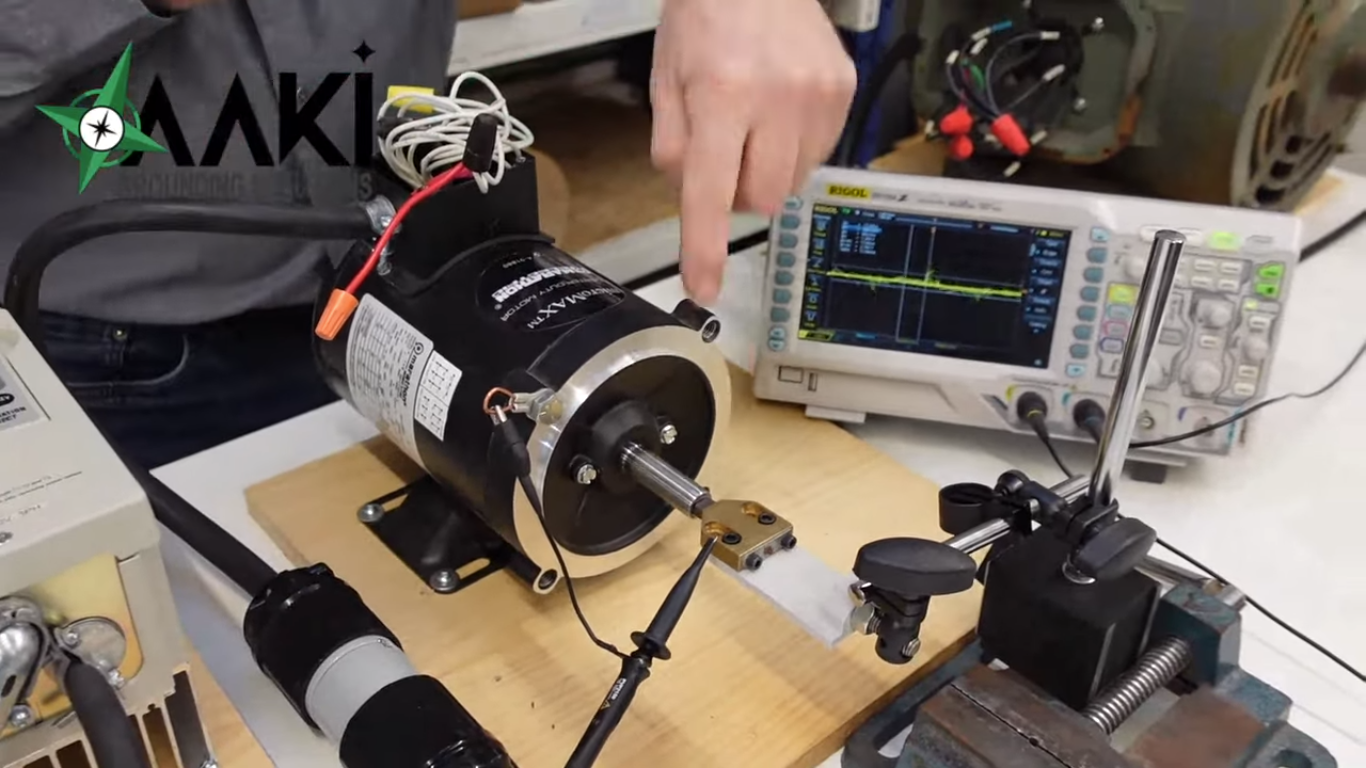

Aaki Motor Shaft Grounding Modules (MSGMs) offer a simple, cost-effective device to eliminate VFD induced bearing failures in three phase induction motors. Modules come in two sizes to fit almost any motor configuration, from fractional horse power to hundreds of HP. They are virtually indestructible and will typically outlast the bearings they are built to protect.

Simple...

However, installation is a big challenge. Motor topologies vary widely, and the endbell / shaft geometry can be challenging, making consistent professional looking installations of MSGMs difficult, time consuming, and typically left to the most skilled machinists in the motor repair shop. Even the simple act of drilling two holes in the motor endbell can be a nerve racking experience that has to be right – you can only do it once.

There has to be a better way...

Aaki manufactures a complete line of spacers, washers and extension plates designed specifically to take the challenges out of installation.

The DrillBuddy™ installation tool is a simple device that makes drilling holes in an endbell simple, consistent and worry free – Right the first time, every time.

FleXmount™ brackets and the FleXform™ tool offer a unique method for securely mounting a MSGM to any endbell geometry, quickly and cost effectively, resulting in a professional job every time.

Aaki Motor Shaft Grounding Modules – A Better Way